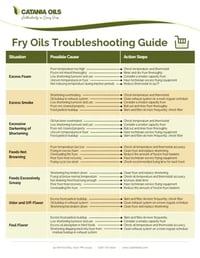

Fry Oils Troubleshooting Guide

Running a kitchen or production line means dealing with constant variables. When your frying oil isn’t performing the way it should, it can slow operations, affect food quality, and increase costs. Our Fry Oils Troubleshooting Guide is designed to give you fast, practical answers so you can diagnose issues quickly and get back to delivering crisp, reliable results.

Best Practices

For Deep Frying

Whether you’re navigating smoky oil, off-flavors, rapid breakdown, or inconsistent coloration, this guide walks you through common causes and proven fixes. With insights from our in-house quality experts, real-world testing, and 125 years of frying oil expertise, you’ll gain a clearer understanding of how to maintain performance and get the most from every drop.

|

Temperature |

|

|

Procedures |

|

|

Filtering |

|

|

Maintenance |

|